Infrastructure

"State-of-the-Art,

Automated Infrastructure, Enabling,

Error-Proof Manufacturing."

LEED compliant Factory campus and Building

Poka-Yoke batching system

It is a type of error-proofing technology used in manufacturing processes to prevent mistakes and ensure accuracy during batching. It streamlines the batching process, reduces waste, and improves product quality.This is the Computer Controlled POKA YOKE Batching System from Rice Lake, USA

Mixing Process controls

Our extensive blending techniques ensure uniform dispersion of ingredients and lessen mixed aging, thus increasing the quality of the mixture. This guarantees that the product operates consistently throughout production after engineering and maintenance, remains effective to the highest possible standards.

Moulding Process controls

Our molding process integrates Poka-Yoke systems and PLCs for precise parameters to control and stable operations. Custom-made fixtures reduce operator fatigue, enhance efficiency, and optimize output, ensuring consistent quality and reliable performance in every production cycle to meet diverse manufacturing needs.

Kneader mixing line

With our kneader mixing line, we can prepare rubber compounds in a homogeneous manner during dynamic process. This complicated PLC controlled Kneader Mixing system enables us to make complicated formulations and achieve the desired material properties to ensure the quality of the resultant rubber.

Mixing mill with stock blender

Our stock blender ensures consistent dispersion in the rubber compounds. By efficiently feeding and blending ingredients, we achieve high-performance rubber blends. This process guarantees a uniform mixture, superior material properties, and reliable quality, meeting the demands of advanced manufacturing standards in this Market.

Mixing Mill for R&D

Our R&D mixing mill enables precise development and testing of new rubber formulations. This specialized equipment allows controlled experimentation, optimizing material properties to a create innovative and custom solutions. We ensure high-quality, reliable rubber compounds tailored to diverse applications and specific performance requirements.

Final mixing line

Our advanced final mixing line ensures precise rubber compounding under controlled conditions. High-capacity mixers deliver uniform material distribution for superior rubber quality. Integrated cooling and quality control systems ensure each batch meets stringent performance standards, guaranteeing reliability and consistency in every production.

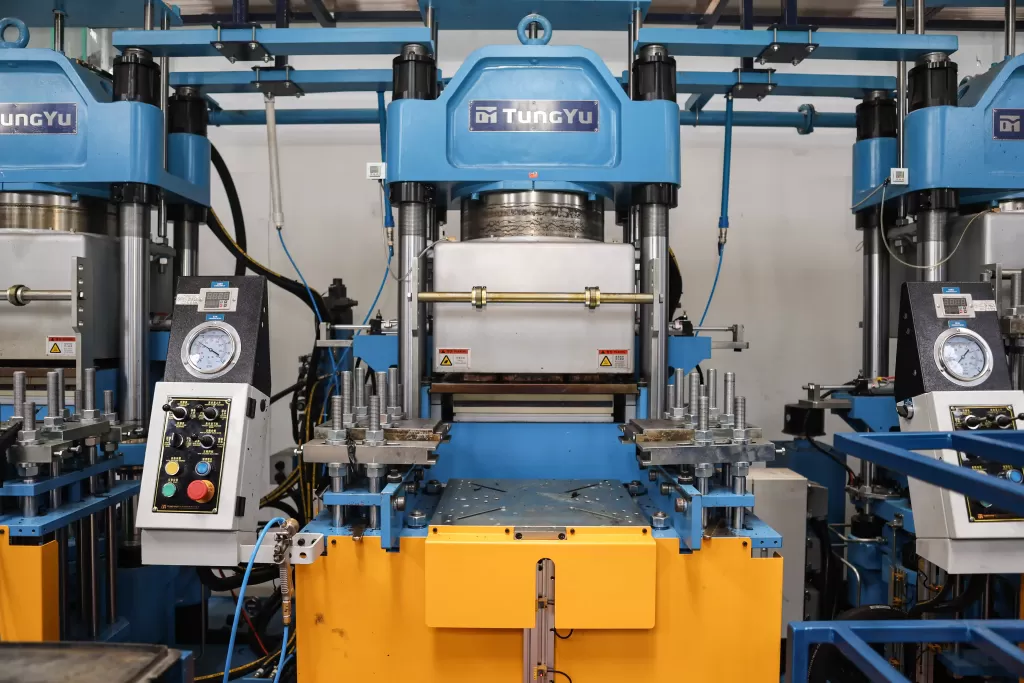

Compression Moulding Presses

Taiwanese – made, compression molding machines offer precision engineering, durability, and advanced technology. Custom designed for rubber and plastic molding applications. These presses ensure consistent product quality and improve production for every product. Maximize efficiency and deliver reliable results for demanding high-performance production.

Computer Enabled Shop Floor for SMART manufacturing practices and Computer Controlled Preforming Machines

Computer Controlled Oven and Surface Coating Systems

Have questions?

Get in touch!